Making the world a place.

Capabilities

-

Manufacturing Capabilities

- Complex Assembly & System Integration

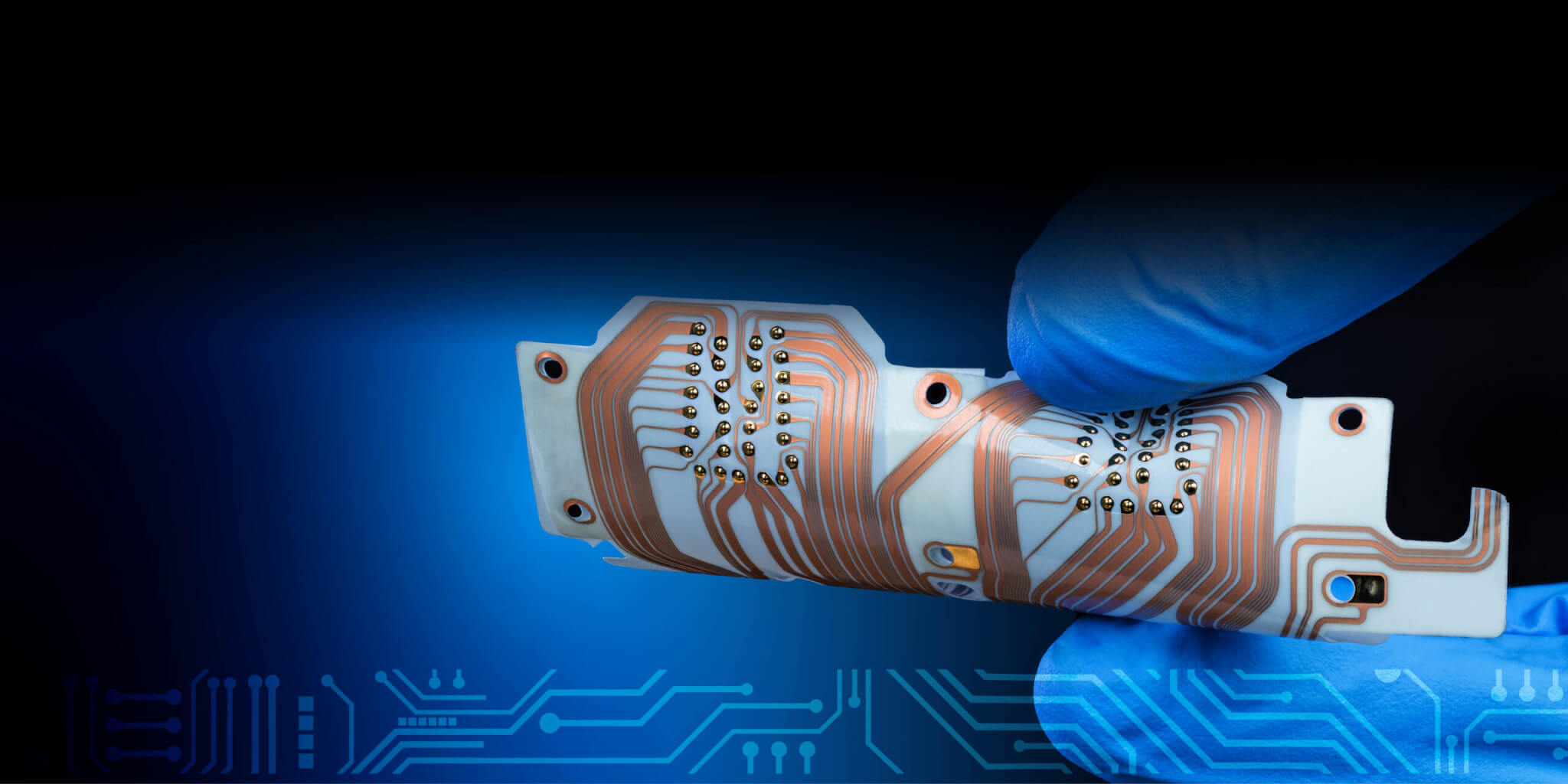

- Electronic Manufacturing Services (EMS)

- EMS Prototyping

- New Product Introductions

- Value Engineering

-

Product Services

- Motors, Fans, Pumps & Blowers

- Printed Electronics

- Engineered Products

-

Material Focused Services

- Metals

- Plastics

- Rubber

-

Engineering Design

- Electrical Design Engineering

- Tooling

-

Management and Quality

- Project Management

- Quality

-

Industry Specific Services

- Medical

- Retail Packaging

Focus Industries

-

Robotics

-

Automation

-

Energy

-

Medical-Wellness

-

Industrials

-

Internet of Things